MetioRITE: A Practical Breakthrough in Gas Detection for Industrial Safety

- MetioRITE

- 7 days ago

- 3 min read

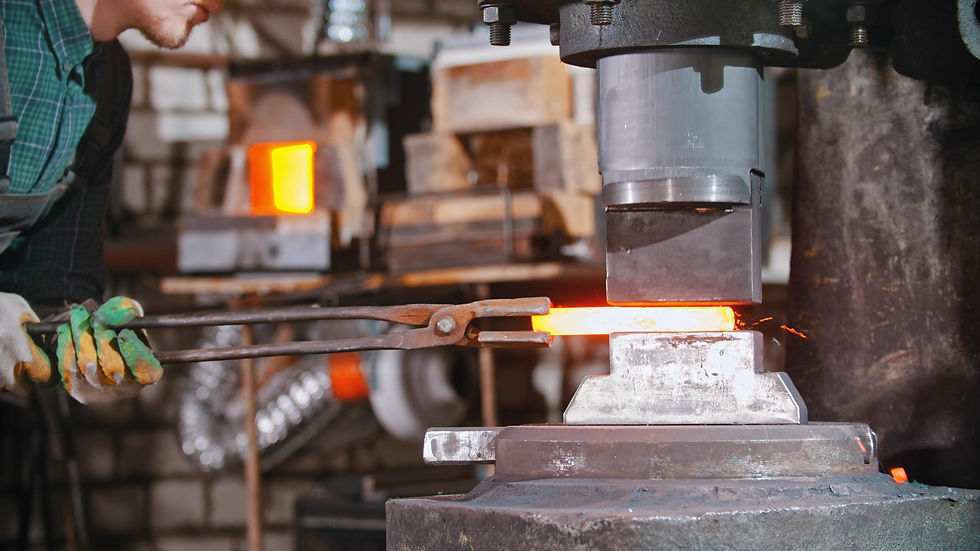

Steel manufacturing and other industrial settings remain hazardous gas exposure hazards. While existing detection systems offer some protection, many fall short of immediate, personal, and visible alerts. MetioRITE fills this critical gap with a compact, wearable gas detection sticker that requires no calibration, no training, and no external device. Designed for frontline workers, MetioRITE directly monitors exposure to eight of the most dangerous gases found in steel plants and alerts users through a visible color-changing mechanism. This second article explores how the technology works, the science behind its reagents, and why it offers a reliable alternative to conventional gas detection solutions.

The Science Behind MetioRITE’s Colorimetric Detection

MetioRITE’s effectiveness lies in its use of chemical reagent dyes that react with specific hazardous gases. Each sticker includes gas-sensitive threads dyed with different reagents tailored to detect ammonia, benzene, carbon monoxide, carbon dioxide, methane, nitrogen dioxide, sulfur dioxide, and low oxygen levels.

When exposed to increasing gas concentrations, the sticker reacts by changing color. For most reagents, this means a shift toward red hue. This makes gas buildup easy to identify even in busy, dimly lit workspaces. The reaction happens as gases diffuse into the threads, triggering a stable, irreversible chemical change that doesn't revert over time.

Importantly, MetioRITE doesn't require external calibration. Each sticker is pre-calibrated for industrial conditions and capable of registering both low-level buildup and sudden spikes. These indicators function in both hot and cold environments and are unaffected by humidity, making them ideal for real-world steel production settings.

Why MetioRITE Stands Out Among Existing Solutions

While gas detectors are not new, many are stationary, expensive, or too complex for routine, shift-based use. Portable electronic monitors must be worn on the chest or clipped to clothing, which may not be in direct view—especially when workers are wearing heavy protective gear or working near extreme heat sources. Additionally, electronic sensors require frequent charging, calibration, and troubleshooting.

MetioRITE offers a simplified, cost-effective alternative. Its adhesive sticker fits easily inside any protective face shield, making it always visible and impossible to overlook. Its minimal weight, slim design, and small size ensure it doesn't interfere with vision or mobility.

Because it doesn’t rely on electricity, MetioRITE can’t be disabled by battery failure or environmental interference. And unlike sensors that monitor ambient air in a room or hallway, MetioRITE provides point-of-contact exposure data: it reads what the worker is breathing in real time.

This feature makes it uniquely qualified to detect toxic gas buildups in confined areas, tunnels, or temporary worksites—environments where centralized monitoring often fails.

Immediate Response and Long-Term Protection

MetioRITE has been designed with safety procedures in mind. At the beginning of each shift, workers apply a sticker to their face shield. If one indicator changes color, they are warned to stay alert. If two indicators turn red, it signals a serious level of accumulated gas, and the worker must evacuate the area and inform their supervisor. This straightforward system requires no interpretation or technical knowledge, ensuring instant action.

Each sticker is single-use and disposed of after one shift, preventing reuse or misinterpretation. MetioRITE’s affordability allows for daily distribution without increasing operating costs, making it a scalable solution for companies, labor unions, and independent contractors alike.

The sticker also includes visual design elements that accommodate color-blind users. The word "DANGER" appears when thresholds are crossed, ensuring safety for all workers.

Raising the Bar for Individual Workplace Safety

With its compact design and low-cost, reliable functionality, MetioRITE has the potential to transform how gas exposure is managed across the steel industry and beyond. It reduces dependency on complex devices, enhances individual accountability, and allows safety to be monitored without distraction or delay.

From health-conscious employers to safety officers and union representatives, MetioRITE gives every stakeholder a practical, deployable tool to prevent overexposure to toxic gases. By prioritizing ease of use and accurate visibility, this innovation stands to become a new industry benchmark in protective equipment—one that saves both lives and long-term healthcare costs.

Bình luận